Refueling

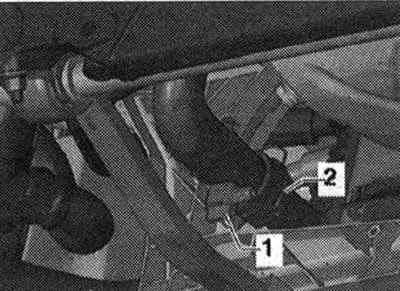

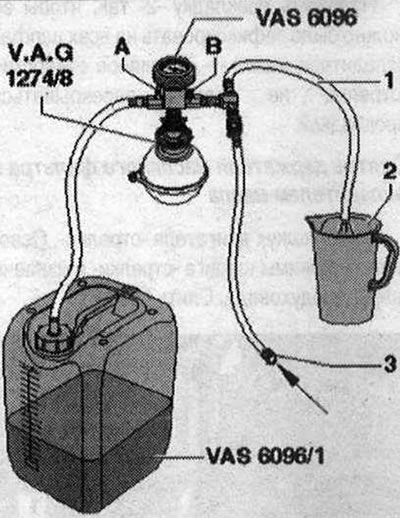

The cooling system is filled with coolant solution and coolant additives for the whole year. Other additives can significantly reduce the anti-corrosion effect. The resulting damage can lead to coolant leakage and, as a result, serious engine damage. Coolant with the correct mixture ratio prevents the formation of corrosion and limescale. In addition, they increase the boiling point. Therefore, concentrate must be present in the cooling system throughout the year. Especially in countries with tropical climates and under high engine loads, coolant with a high boiling point reliably protects the engine during operation. The freezing temperature of the coolant must be at least -25°C (in countries with an arctic climate - no less than -35°С). It is also prohibited to reduce the proportion of concentrate in the coolant during the warm season or when operating in countries with warm climates by adding water to the cooling system. The proportion of concentrate must be at least 40%. If, due to climatic conditions, it is necessary to reduce the freezing point of the coolant, the additive content can be increased, but not more than 60% (The freezing temperature in this case will be about -40°C). If this limit is exceeded, the freezing temperature of the coolant will increase again, and, in addition, the efficiency of the cooling system will decrease. To mix coolant, use only clean drinking water. When replacing the radiator, heater heat exchanger, cylinder head, cylinder head gasket or cylinder block, reuse of drained coolant is prohibited. Contaminated coolant cannot be used for further use. To check the concentrate in the cooling system, use a refractometer -T10007-. Component ratio in coolant: Additive (40%) and coolant (60%) to ensure a freezing temperature of -25°C. Additive (50%) and coolant (50%) to ensure a freezing temperature of -35°C. Additive (60%) and coolant (40%) to ensure a freezing temperature of -40°C. Close the drain plug. Fill the coolant reservoir with 8 liters of coolant, pre-mixed with the additive in the correct proportion: Screw on the cooling system tester adapter -VAG 1274/8-k extended. tank. Install the coolant filling tool onto the adapter -VAG 1274/8-. Place the bleeder hose -1- into a small container -2-. The exhaust air entrains a small amount of coolant, which must be collected.

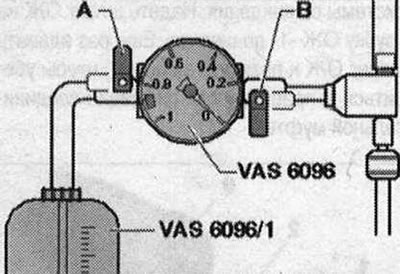

Close valves -A- and -B- by turning them perpendicular to the direction of flow. Connect hose -3- to the compressed air line. Excess pressure: 6...10 bar. Open valve -B- by turning it in the direction of flow. A vacuum is created in the cooling system using an ejection pump; the indicator arrow should be in the green field. Open tap -A- briefly, turn it parallel to the direction of flow so that the hose of the reservoir tank of the device for filling the cooling system is filled with coolant. Close tap -A- again.

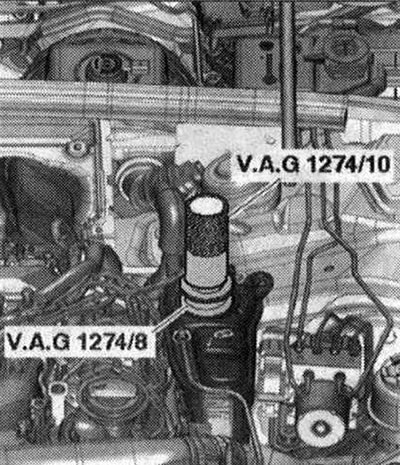

Open tap -B- for 2 minutes. A vacuum continues to be created in the cooling system using the ejection pump; the indicator arrow should be in the green field. Close tap -B-. The indicator arrow should remain in the green field; in this case, the vacuum in the cooling system will be sufficient for its subsequent filling. If the arrow is below the green field, then the previous operations should be repeated. When the vacuum decreases, check the cooling system for leaks. Remove the compressed air hose. Open tap -A-. Thanks to the vacuum, the coolant leaving the reservoir for filling the cooling system fills the system. Remove the tool for filling the cooling system from the adapter -VAG 1274/8- to the extension. tank. Place tube -VAG 1274/10- onto adapter -VAG 1274/8-.

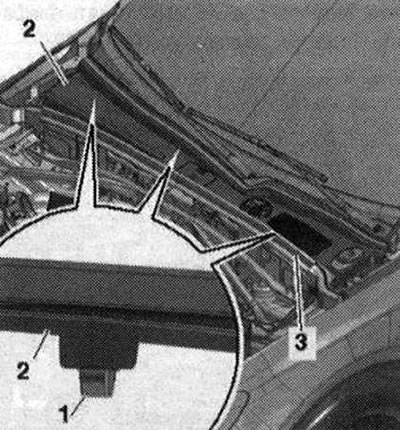

Remove seal -3-. Release the mounting clips -1- from the mountings and remove the plenum chamber cover -2-.

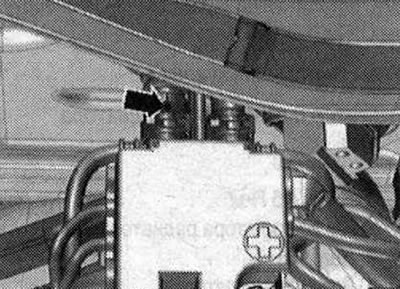

Unscrew the coolant hose to the heat exchanger and pull it back until the vent hole in the coolant hose -arrow- is not blocked by the connecting piece. Fill with coolant until it begins to flow out of the coolant hose vent. Place the coolant hose onto the connecting piece and secure it.

On vehicles with auxiliary heater, turn on the heater for approx. for 30 seconds. Close the extension cover. tank. Start the engine. In all zones, set the temperature to "NG". Turn off the compressor by pressing the |esop| button. The engine should run at 2000 rpm for 3 minutes. Leave the engine idling until the 2 large coolant hoses on the radiator warm up. The engine should run at 2000 rpm for 1 minute. Turn off and allow the engine to cool. Install the front soundproofing screen. Check coolant level. When the engine is cold, the coolant temperature level should be at the MAX mark. When the engine is warm, the coolant level should exceed the MAX mark.

Visitor comments